The following is an excerpt from our Enriching Data, Empowering Action whitepaper. You can access the full report here.

What took ground teams six months to inspect, took PrecisionHawk’s drone operators and data analysts just six weeks.

In early 2019, a Southeastern electric utility that covers over 100,000 square miles scheduled an inventory of assets before implementing IVVC activation, an implementation that reduces energy demand.

After realizing that their incumbent provider’s manual methods of data collection, processing, and analysis were too slow—and that the data it provided was lacking in quality—the utility partnered with PrecisionHawk to increase the accuracy of its asset data and speed the time to IVVC activation.

PrecisionHawk was tasked with updating the utility’s inventory and phasing of more than 275,000 structures. Since the project was already a few months in, it was crucial that PrecisionHawk build a solution that could collect accurate data at a very fast pace.

Based on the requirements and timeline, PrecisionHawk designed a solution that would streamline each aspect of the asset management lifecycle, from data collection through reporting and action:

-

PrecisionHawk’s credentialed drone pilots executed flights tailored to the project specifications, and captured the required images and data with RGB cameras; in the meantime, the pilots also served as ground teams, using a tablet app created by PrecisionHawk that streamlines manual data entry.

-

The drone pilots captured images of each pole from various angles as well as the next pole down the line, plus images of complicated equipment like capacitors and reclosers for future inspection purposes.

-

The collected data—over a million images—was uploaded into PrecisionAnalytics, to apply machine vision, conduct change detection, and identify areas of concern.

-

Utility stakeholders received, via PrecisionAnalytics, reports and images showing the location of each asset and the phasing of each overhead conductor. This was served up in a view that allowed the utility to see all the poles inspected, the associated images, and any changes PrecisionHawk made to the utility’s database.

The utility then had an accurate representation of their inventory, plus data on the phasing of their circuits. Using the data collected and analyzed by PrecisionHawk, just six months into the project the client gained unprecedented insight into the type and location of its assets.

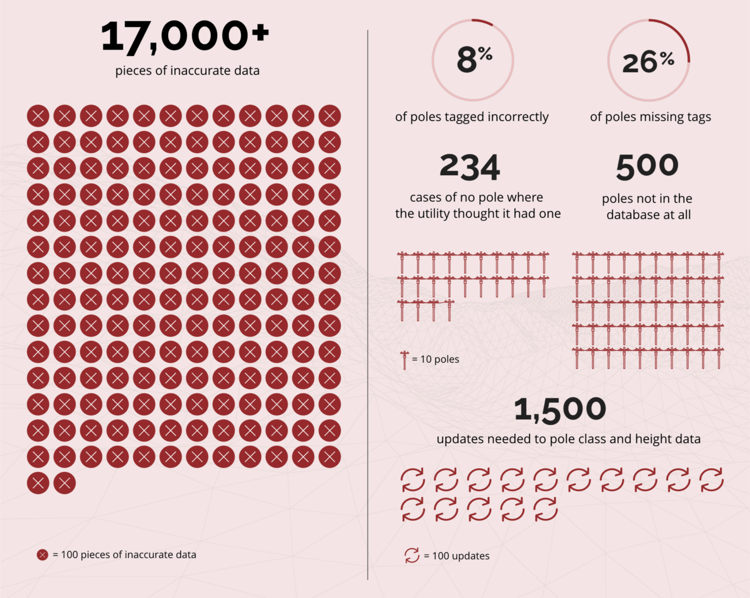

Excerpt from our "How a Utility is Accelerating its Modernization Efforts with PrecisionHawk" infographic

Using PrecisionHawk’s solution for data collection, processing, analysis, and reporting, the utility sped up the inventory process, gained unprecedented insight into the type and location of its assets, gathered needed data on phasing—and made incredible headway in its modernization program.

The bottom line: by deploying PrecisionHawk’s data solution, enterprises can improve every step of their inspection process—from collecting data to deploying repair crews.

Download the full Enriching Data, Empowering Action whitepaper today to learn how data-powered decision-making can help you reduce downtime, increase safety, and lower costs.