SUBSTATION INSPECTION

Learn how GIS inspections yield better results through faster, safer data collection and analysis—so you can better manage your substations.

Conduct Faster, Safer Substation Inspections with More Accurate Data

Our industry-leading geospatial technology portfolio, engineered for substation inspection:

DISCOVER

Define shot sheets and data delivery requirements. Because the amount of data to be collected on a substation application is lower than on transmission or distribution applications, operators can use the highest-resolution cameras—and, for drone projects, the largest drones—and still be cost-effective.

COLLECT

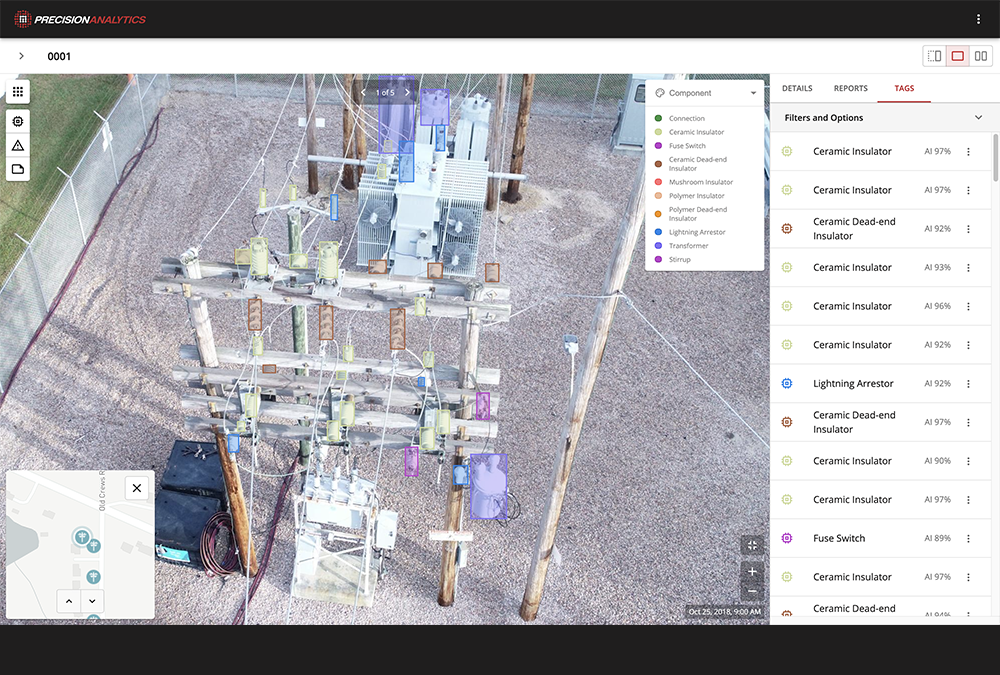

Deploy drones with triple redundancy in and around substation to capture RGB, visual, and LiDAR imagery that offers detail on the finest components. Supplement with ground inspection.

PROCESS

QC data and call-in any “criticals” identified while in the field. Our team of data analysts produces structural models using LiDAR data, delivering precise measures of pole height, depth, health, lean, and attachments.

ANALYZE

Evaluate substation conditions using imagery. For new construction or rebuilds, 3D models let you validate the delta between what was intended to be built and what was actually built, or determine whether ordered changes have been made.

REPORT

Produce a report highlighting areas of concern. Use collaboration tools to empower teammates and vendors.

ACTION

Deliver imagery and 3D models to O&M and engineering for detailed planning and budgeting.

- Refine capital budgets using a comprehensive accounting of your assets, including precise geolocation

- Increase compliance with regulations using an inspection method that reduces the risk of outages and fires

- Prioritize improvements based on the severity of damage using exact indicators of asset health

- Plan future construction

- Apply for permits and produce planometrics

- Fuel network engineering strategy, modeling out-of-compliance assets in relation to other assets, roadways, and zoning

- Prove regulatory compliance

- Detail work orders, with robust imagery, to repair immediate issues