The following is an excerpt from our solution brief, Electrical Distribution Pole Lifecycle Management, where we explore how drone-based technology is transforming electrical distribution operations. Download the solution brief to learn how you can create and deploy a drone-based solution to reach new levels of safety and efficiency in collecting, processing, and actioning electrical distribution pole data.

Around 185 million utility poles dot the U.S. landscape—all of which need to be surveyed and inspected regularly to keep them safe and functioning.

However, traditional inspection methods come with challenges. Using crews to regularly inspect utility poles is a dangerous process—and inspecting assets over thousands of miles, some of them inaccessible by foot, is so slow that it’s challenging to inspect the poles as frequently as needed. Approximately 2.5 million poles are replaced annually, for example, yet half of the poles in Los Angeles are over 50 years old, with some even exceeding 90 years. Plus, workers have to fight through vegetation, intrude on people’s property, and sometimes climb poles or inspect them from an aerial lift.

Beyond issues with the inspection method itself, lackluster data and recordkeeping can impair maintenance efforts. If inspection data isn’t standardized and stored properly, asset managers can experience difficulties predicting failures, identifying problematic components system-wide, and conducting other critical analyses.

To address these challenges, utility operators are turning to drone-based technology.

PrecisionHawk provides a drone-based electrical distribution pole management solution that includes data collection, processing, and reporting in a streamlined manner. The resulting reports can be referenced directly to resolve issues. And data can be incorporated into asset management or enterprise resource systems to automatically prescribe action.

Through our work with some of the biggest utilities companies, we’ve seen results:

- Less downtime due to unforeseen damage

- Fewer manual missions

- Higher inventory and pole health measurements accuracy

- Reduced inspection costs

- Faster fixes to issues and greater production per tower

- Higher margin of safety

Collecting data

Distribution poles present a challenging operational environment for unmanned aircraft. After all, the assets may be located in windy or wet areas, and their power lines are difficult to maneuver around. However, our drones are purpose-built for such a challenging environment. They’re lightweight, but rugged, and include rotor blade guards to mitigate the damage that could occur on contact.

-1.jpg?width=5472&name=Zenmuse%20XT%20on%20drone%20close-up%20(1)-1.jpg)

In addition to a standard visual sensor, our drone operators deploy thermal, LiDAR, and multispectral sensors. From identifying overheating equipment to measuring the load on a pole and quickly identifying encroaching vegetation, these sensors detect what would otherwise be difficult or impossible to identify with the naked eye.

Operating flight software: PrecisionFlight

To execute missions, our pilots use PrecisionFlight. The software’s intelligent flight planning enables operators to deploy manual, semi-autonomous, and fully autonomous missions that comply with regulations and safety management systems.

A typical mission looks like this:

- Prior to a mission, the drone operator defines a flight plan by combining distribution pole specifications with 3D geospatial data, such as the surrounding terrain and no-fly zones.

- To identify potential issues, they emulate the flight in PrecisionFlight, setting additional boundaries as necessary.

- Once on-site, operators load the plan (no connectivity required), deploy the drone, and monitor it—using flight telemetry—as it automatically captures data along a precise flight path, predetermined by a set of waypoints.

- The drone captures imagery of all the components of the distribution pole from all angles. If issues requiring further inspection surface during autonomous flight, the operator can manually navigate to the area of concern. In the case of load analysis, operators deploy a LiDAR sensor to collect dense point cloud data.

- After the mission, the pilot can “replay” the mission to assess mission efficacy and optimize the flight plan.

While gaining a measure of asset conditions at a single point in time is useful, you can obtain greater insight by tracking trends over a given period. Using PrecisionFlight’s repeatable flight plans, operators are able to capture multiple data sets, from separate missions, that precisely correlate.

Conducting safe and effective flight operations

Beyond flight software, the skills of your drone operators are critical to the safety and effectiveness of your drone-based inspections. The pilot in command must understand your objectives and follow rigorous procedures, regardless of whether they’re your own staff or PrecisionHawk’s experienced flight operators.

To meet these requirements, PrecisionHawk’s leaders—many of whom are former Navy Top Gun pilots—developed our industry-leading drone operating procedures:

- Mission Requirements: Understand the assets and area of interest to be inspected, and the specific requirements of the mission.

- Mission Readiness: Complete a rigorous training program for the complete mission lifecycle, from analyzing airspace around distribution poles to managing unusual asset configurations and weather patterns.

- Procedure: Follow flight standards, a comprehensive mission checklist, safety management systems, and incident protocols.

- Regulatory Compliance: Comply with guidelines, designed by our policy analysts, to limit regulatory exposure.

- Quality Assurance: Verify that the data meets quality requirements using PrecisionHawk’s offline field analysis tool; identify anomalies, omissions, and other issues prior to delivery.

- Data Secure Chain of Custody: Protect mission data by following secure transportation, transmission, and destruction protocols.

- Continuous Improvement: Engage in a continuous improvement plan, reporting lessons learned and applying them to future operations.

These are principles we require of all PrecisionHawk’s flight stakeholders. Whether they’re our 100-plus full-time pilots, the more than 15,000 pilots in our drone pilot network, or our clients’ own staff, we’ve designed our training regimen to help professionals of any background achieve this standard of excellence. And everyone, from program directors to visual observers, is responsible for maintaining discipline in the field.

A streamlined system of integrating data

After you collect inspection data, you need a focused system for analyzing and processing it. Traditionally, inspectors store reports and imagery in a GIS data or manual file storage system. But these solutions can be messy and inaccessible, especially for non-technical stakeholders.

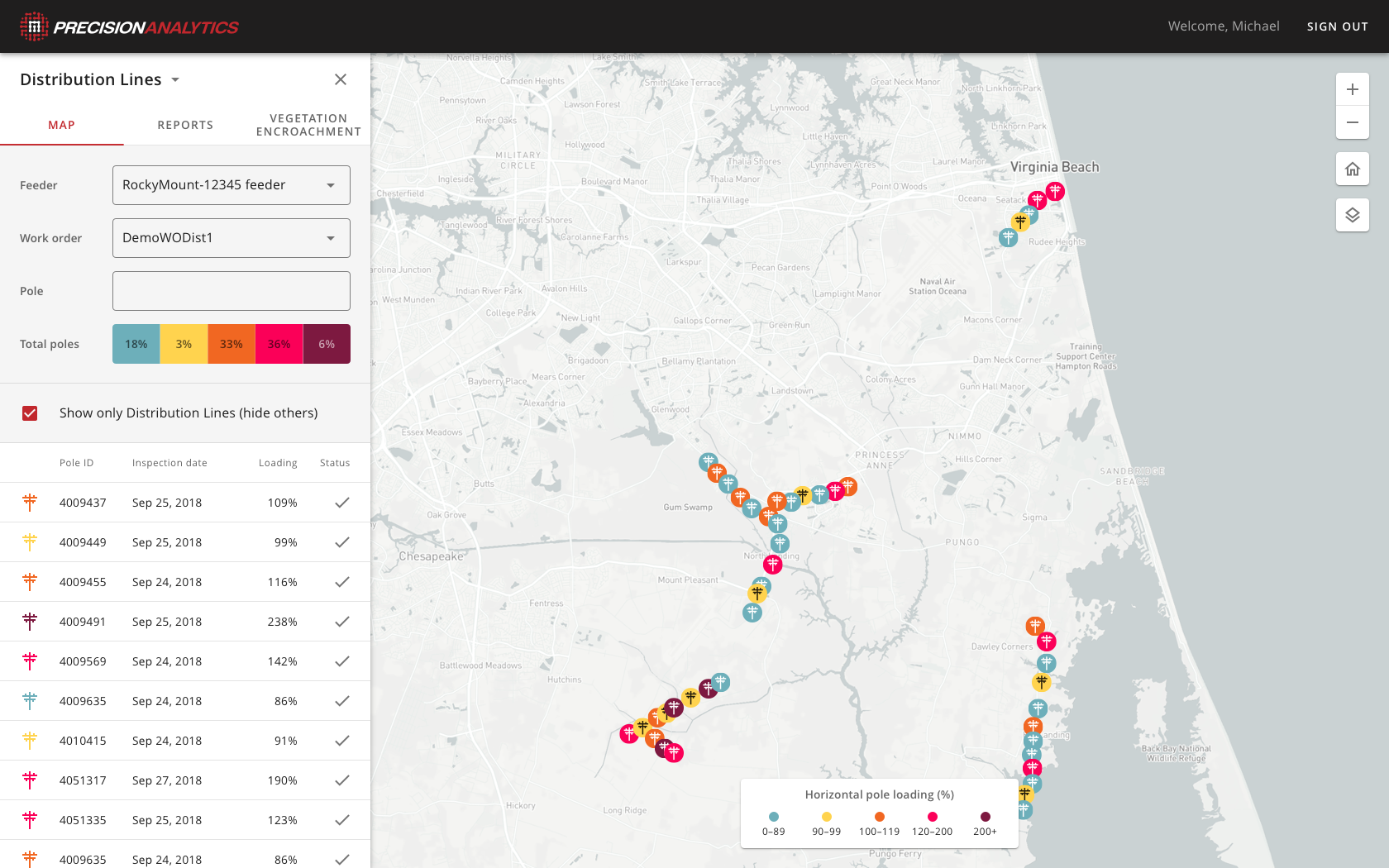

With our aerial intelligence platform, drone operators can upload data and imagery into PrecisionHawk’s cloud-based system, PrecisionAnalytics Distribution, which cross-references the uploaded imagery against thousands of terabytes of data, flagging issues.

After machine intelligence identifies imagery that represents priority issues, it aggregates the data into an intuitive, web-based interface that’s accessible from anywhere.

PrecisionAnalytics Distribution features include:

- Site Statistics: Get a comprehensive view of all your assets, including distribution poles and transmission towers, wind turbines, and solar panels—either separately or all at once. Segment your health trends at the portfolio or site level: view rolled-up statistics on damage severity, issues, and other measures you identify.

- Wind load data. The wind load analysis outcomes are delivered via PrecisionAnalytics Distribution, so you know which assets aren’t compliant with government regulations.

- Vegetation map: View an encroachment map overlaid on on a street map, or in a 3D point cloud model, to ensure the areas around assets are clear.

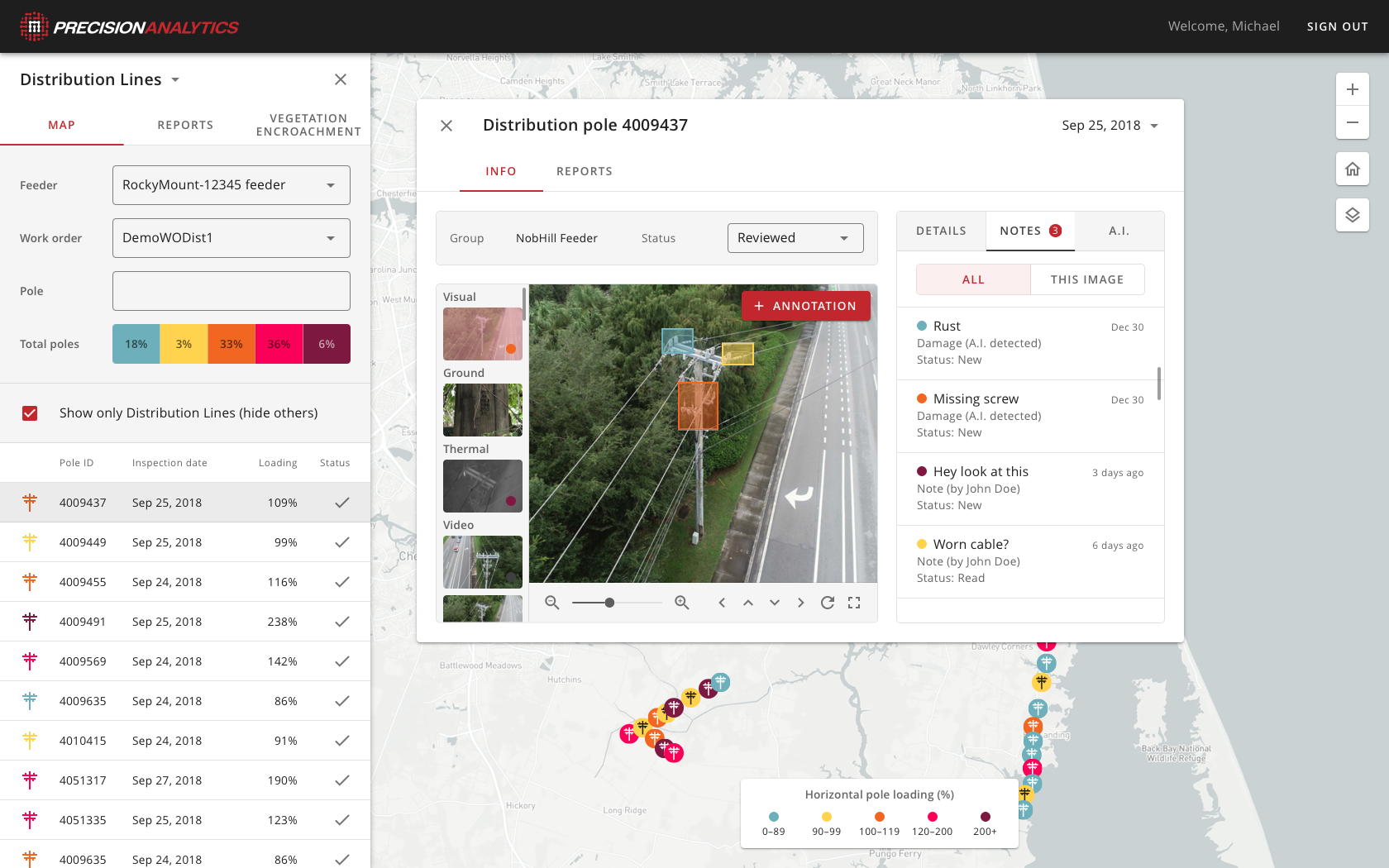

- Distribution Poles at-a-Glance: Hone in on problem areas, such as wood decay or a split pole top. Review the overall health of distribution assets and navigate image sets using intuitive markers, color-coded for damage severity.

- Detailed Views: View full-resolution imagery and zoom in on key issues.

- In-situ Communication: Create and edit annotations and store metadata, such as the type of observation, your finding, the size of the issue, damage severity, and other parameters. Add comments to other stakeholders.

- Historical Recordkeeping: Investigate the genesis of an issue. View historical imagery for the same location pole from prior inspections to identify potential precursors to the issue at-hand.

Typical issues that analysts identify using drone-based imagery include:

- Cracked insulators

- Corrosion

- Vegetation

- Split, leaning, and otherwise damaged poles

- Open fuses

- Conductor issues

- Overheating equipment

Our team of data analysts can produce these annotations or we can leave it up to you.

Actioning data

Once analysts have produced their findings, others need to take action. But how do you give cross-functional and external stakeholders the insights they need (without exposing them to the voluminous detail)?

PrecisionAnalytics Distribution’s flexible reporting and integration features enable you to distribute information across your organization—whether it be exporting an Excel and Word document or integrating with other software, such as Enterprise Resource Planning (ERP) and asset management systems. This allows for faster fixes to pole issues and therefore, greater production per tower.

Put drone-based aerial intelligence to work

Partner with PrecisionHawk to create and deploy a drone-based solution in electrical distribution pole inspections. We’re replacing slow and dangerous ground, bucket truck, and pole-climbing work with drone deployments; hours of tedious image review with machine intelligence; and data overload with a focused system of reporting.

Download our full solution brief for more details on how you can use drone-based aerial intelligence in the electrical distribution pole lifecycle.

To speak with one of our consultants about our Electrical Distribution Pole Solution, contact us.