The following is an excerpt from our ‘Managing Assets with a Drone- and Data-Driven Solution’ guide. You can access the full guide here.

For many electric cooperatives, drones are an ideal way to start using technology solutions to speed up and increase the accuracy of asset inspections. The next step after that is often to invest in more advanced technology to make the best use of all the rich data collected. Because you'll get a large amount, it’s key to consider how that data can later be integrated into your existing workflows.

By combining drone data collection with processing and reporting into a streamlined, end-to-end data solution, PrecisionHawk has made it easier to turn a massive amount of data into actionable insights. It accelerates, automates, and amplifies data analysis to reduce human error, increase speed and efficiency, and decrease costs.

We’ve built our software to integrate with your enterprise data management systems and asset management systems, so you can leverage aerial intelligence across the entire distribution pole life cycle, from the selection of future structure sites to the decommissioning of assets.

Understanding the Data-Driven Workflow

If you’ve collected a lot of data—say an entire distribution line’s worth—manual processing can take anywhere from one week to more than four weeks. Human analysts must slowly and carefully rectify the data, look for component issues, and compare the data to existing information in the system so that it’s usable and actionable.

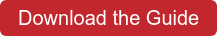

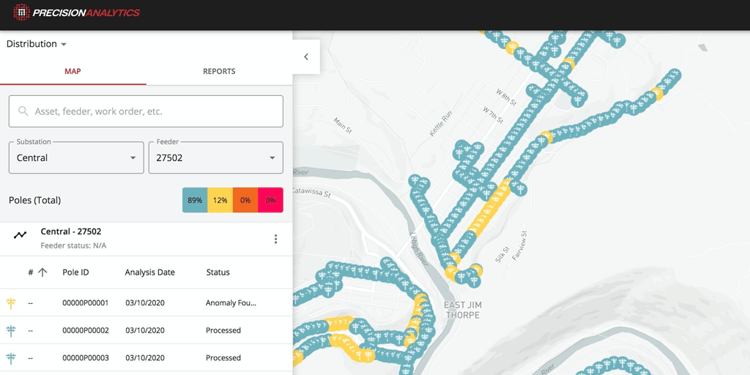

A solution that leverages artificial intelligence and machine learning, on the other hand, can speed up the inspection process, more easily identify problems, and let you reallocate your human resources to more valuable tasks.

With the PrecisionHawk data solution:

- A large volume of data is collected, increasing the likelihood of obtaining an ample number of high-quality, useful images.

- Machine learning flags those images that show areas of concern, so the co-op staff doesn't have to analyze thousands of images.

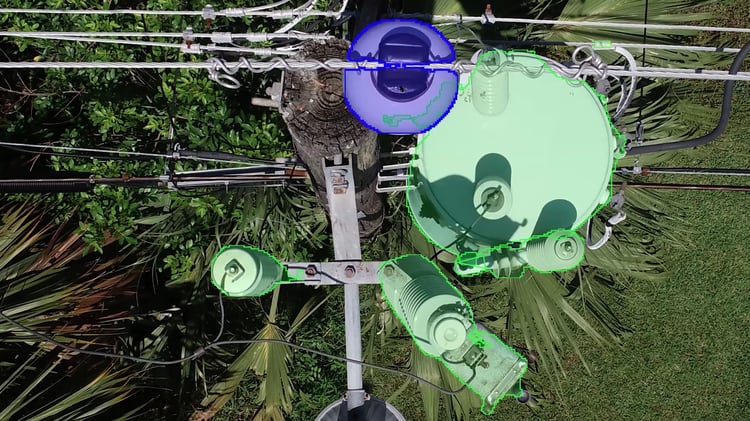

- Artificial intelligence generates actionable reports so the program managers, dispatchers, and operations staff can take quick action on needed repairs.

Decreasing Risks with a Data-Driven Solution

An AI- and ML-driven solution can also help co-ops mitigate the risks that are inherent with running a utility, from worksite injuries to running afoul of regulations.

Easily File Insurance Claims and Comply with Government Regulations with Robust Reporting

In one click, co-op managers and directors can download a spreadsheet that catalogs distribution pole metadata, including a link to reference imagery. For greater detail, you can export a document that includes supplemental instructions and information, such as diagrams, definitions, and procedures.

This feature is particularly useful for informing stakeholders that have limited scopes of work. For example, you might export reports to:

- Detail an insurance claim after a storm

- Strengthen an insurance risk assessment

- Claim a warranty issue

- Inform a field maintainer prior to taking action

- Offer detail to regulatory reporting

These shareable, easy-to-read reports can help streamline and expedite reporting and claims, increasing the chances of a positive outcome.

Faster, More Accurate Inspections Reduce Danger of Asset Failure

With a data-driven, UAV-based inspection solution, a co-op can quickly identify anomalies and send out repair crews—before a small problem turns into a big one and causes fires, power outages, or other dangerous situations. “With the UAV, we can get out there more often,” says Stan McHann, Senior Research Engineer at NRECA. “We can actually create actionable results to fix a lot of problems before they happen.”

Keep Sensitive Data Safer

It’s crucial that software systems for creating and handling electric co-op data are designed with security in mind for today and tomorrow. “While there are major weaknesses in the distribution system, which are vulnerable to exploitation [...] there are myriad new attack vectors being added every day,” report Reza Arghandeh and Yuxun Zhou in their book Big Data Application in Power Systems.

When sensitive data resides in multiple stakeholders’ systems, that risk is multiplied. The more places data is stored, the more opportunities there are for bad actors to find vulnerabilities.

PrecisionHawk provides a multi-tenant, cloud-based experience—which means each tenant's data is isolated and invisible to other tenants. Code scans, third-party audits, and automated testing ensure that new vulnerabilities or threats are not introduced.

We also hold ISO certification, meaning its processes meet all the quality, safety, and efficiency requirements of the International Organization for Standardization.

Deliverables: The Data Value Chain

When a co-op partners with PrecisionHawk to add a data solution to their drone program—or to implement both together—the deliverables form a Data Value Chain, where each professional, procedure, and tool adds value to the final outcome.

This data value chain is focused primarily not on the volume of the data, but the quality of the data. Obtain the right data during the discovery and collection phases is essential to move forward to processing. With this data value chain, PrecisionHawk’s solution is purpose-built for the entire data lifecycle.

To increase uptime, comply with regulations, reduce the risk of catastrophic failure, increase member satisfaction, and make an impact on their organizations, co-op managers and directors need deeper insight into their distribution assets.

In our guide, Managing Assets with a Drone- and Data-Driven Solution, we’ll demonstrate how PrecisionHawk’s team can help co-ops considering a drone-based solution every step of the way.