The following is a recap of this year’s AUVSI XPONENTIAL Keynote Address, delivered by PrecisionHawk CEO Michael Chasen and Florida Power & Light Company’s Lead Project Manager Eric Schwartz.

Uptime is paramount in the utilities industry, requiring operators to conduct regular inspections to ensure assets are functioning properly. However, traditional inspection methods need improvement.

“The current utility standard to inspect assets is human-dependent and manual, which has a low level of accuracy and can miss critical issues,” said Eric Schwartz, Florida Power & Light Company’s Lead Project Manager. “Florida Power & Light Company is using drone-based technology to transform these inspection methods and has plans to fly over 10,000 miles in 2019, using aerial intelligence to process the data.”

WIth drone-based technology, utility operators can replace slow and dangerous ground, bucket truck, and pole-climbing missions with drone deployments; hours of tedious image review with machine intelligence; and data overload with a focused system of reporting.

More and more companies are realizing the significant positive impact drone-based technology has on operations, especially with recent advancements in the industry.

“Thanks to distributed networks of drone operators, beyond visual line of sight (BVLOS) flights, and A.I., we’re about to hit the exponential growth [the drone industry has] been waiting for,” said Michael Chasen, PrecisionHawk’s CEO.

Collecting data

Distributed networks of drone operators are allowing drone-based data capture to become as fast and accessible as ever before. With PrecisionHawk’s Drone Pilot Network, customers get immediate access to 15,000+ drone operators who are available to fly any site in the U.S. within 24 to 72 hours. This model enables companies to quickly collect the data they need, whether it be to complete a routine maintenance check of an asset or assess damage after a storm.

Beyond visual line of sight (BVLOS) flight is also “changing the equation” of drone-based data collection. Though federal authorization to conduct such flights is limited, those drone operators—including PrecisionHawk—that are permitted to deploy BVLOS operations are no longer limited to keeping their drone within direct view during flight. This is especially useful for utilities, which manage lines that traverse vast, sometimes mountainous terrain—or offshore locations.

By flying BVLOS, drone operators are able to cover more area and collect more data per deployment than if they were to fly within visual line of sight (VLOS).

BVLOS flights require a hard-to-get waiver from the Federal Aviation Administration (FAA), for which applications are rejected at a rate of 99%.

Fortunately, PrecisionHawk was granted the very first waiver that covers BVLOS flight in Class G airspace. We aren’t restricted to a particular jurisdiction or a particular type of drone, which means we can apply this waiver to conduct more efficient drone operations on our customer’s behalf.

“We worked closely with the FAA and other organizations to produce the Pathfinder Report, which identified safety procedures and technologies that companies can utilize to fly beyond the 1-mile VLOS limit,” said Chasen. “In fact, we’re one of a dozen companies that are allowed to fly BVLOS, and we’ve seen it change the way data is collected.”

Processing and analyzing the influx of new data

As advances like drone operator networks and BVLOS flights expand the scale of drone-based data collection, companies are producing a volume of a data that cannot be efficiently processed without the aid of machines.

To aggregate and analyze this deluge of data, Schwartz and FP&L are utilizing machine vision and machine learning.

“Florida Power & Light is a huge Six Sigma Company—we take quality very seriously—so we did a Gage R&R,” said Schwartz. “Statistically, we proved out the A.I. makes a difference: it’s better than the human-side.”

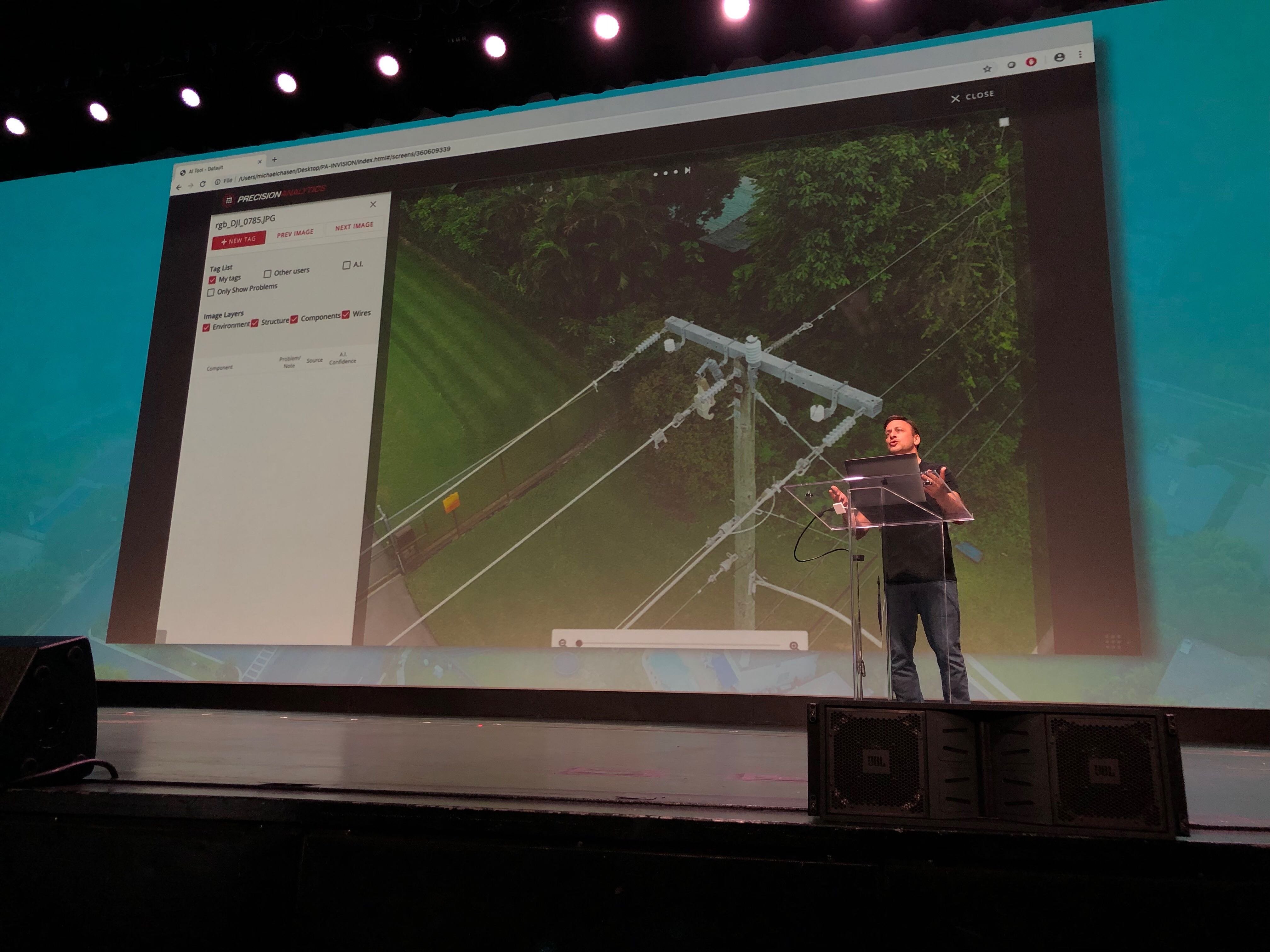

One such A.I. solution is PrecisionAnalytics, PrecisionHawk’s newest aerial mapping, modeling, and inspection platform. It allows users to apply the latest generation of machine vision to their data and imagery, thereby automating analysis and streamlining reporting.

It’s simple to use. After a mission, drone operators upload data and imagery into the cloud-based system, which cross-references the uploaded imagery against thousands of terabytes of data, flagging issues. Machine vision technology then identifies imagery that presents priority issues and aggregates the data into an intuitive, web-based interface that’s accessible from anywhere.

Typical issues that analysts identify using drone-based imagery of utility assets include:

- Cracked insulators

- Corrosion

- Vegetation

- Split, leaning, and otherwise damaged poles

- Open fuses

- Conductor issues

- Overheating equipment

Once these issues have been identified, the software’s flexible reporting and integration features enable users to distribute information across their organization—whether it be exporting an Excel and Word document or integrating with other software, such as Enterprise Resource Planning (ERP) and asset management systems. This allows for faster fixes to issues.

“The true value of drones and machine learning is that we’re becoming predictive - rather than reactive - in maintenance operations,” said Schwartz. “Drones and machine learning are not only identifying the problems of today, but also the potential problems of the future.”

Speak with a PrecisionHawk solutions expert about how drone and A.I. can help you identify the problems of the future.